In modern food manufacturing, hygiene and safety are not just operational requirements—they are strict regulatory standards. Every aspect of a food production environment, from ingredient handling to packaging, must comply with safety systems such as HACCP (Hazard Analysis and Critical Control Points). One critical yet often overlooked component of these systems is the use of Blue Detectable Plasters.

As a professional Blue Detectable Plasters manufacturer, Suzhou Sunmed provides reliable, food-safe solutions that protect workers’ wounds while ensuring maximum product safety. Below, we explore where and why these plasters should be used in a food factory, along with Suzhou Sunmed’s product advantages and their key role in contamination prevention.

Understanding the Role of Blue Detectable Plasters in Food Safety

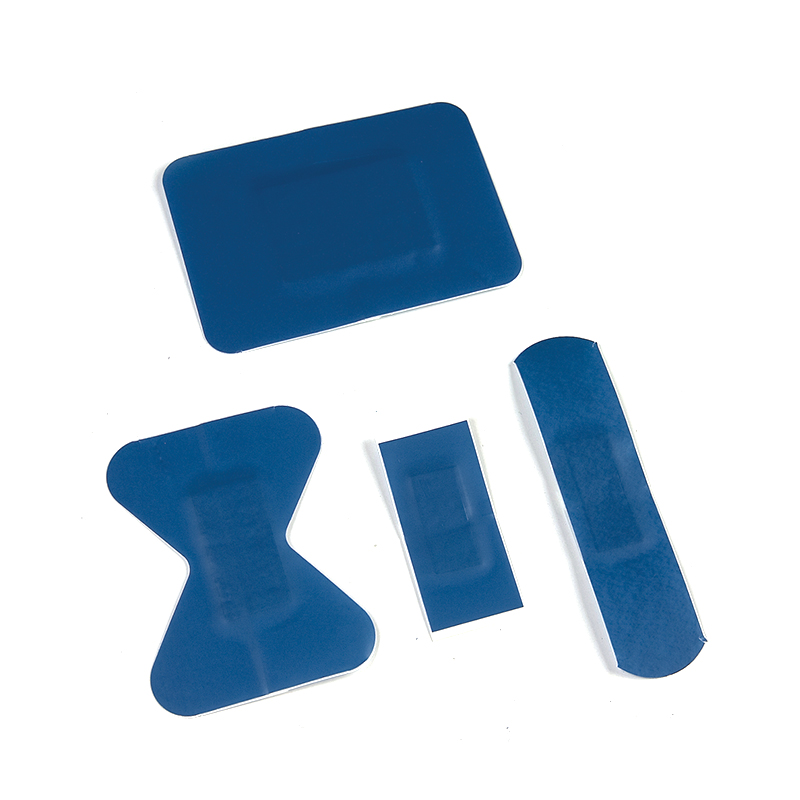

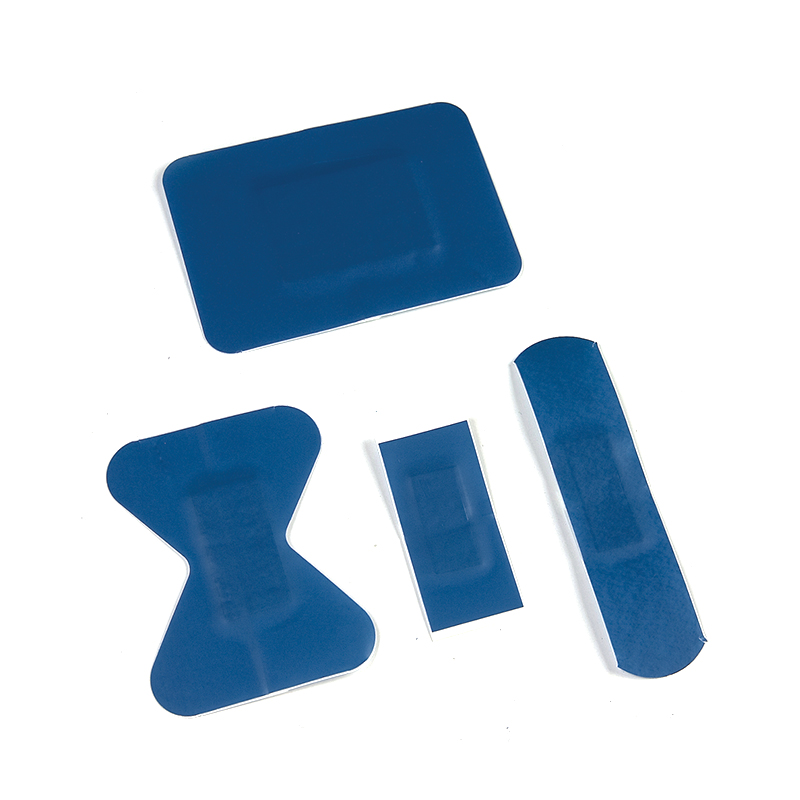

Blue Detectable Plasters are specially designed adhesive dressings used in food processing and packaging environments. They are easily visible and detectable by metal detectors or X-ray inspection systems, ensuring that if a plaster accidentally falls into a production line, it can be quickly located and removed.

This dual-detectable design—visual and metallic detection—plays a vital role in preventing foreign object contamination, one of the most serious hazards in the food industry.

Key Application Areas in a Food Factory

(1) Food Preparation and Handling Zones

These are the areas where ingredients are washed, chopped, mixed, or processed. Workers are constantly handling knives, machinery, and sharp tools, making small cuts or abrasions inevitable.

Using Suzhou Sunmed Blue Detectable Plasters here ensures that:

Any lost plaster is immediately visible against food products (the blue color doesn’t occur naturally in food).

Metal detectors in the line can instantly detect the plaster material, preventing contamination.

(2) Production and Packaging Lines

In automated production areas, any foreign object can cause contamination or damage machinery. Blue Detectable Plasters are required for all staff working near conveyors, packaging equipment, or filling stations.

Suzhou Sunmed’s plasters adhere strongly even in humid or refrigerated environments, maintaining protection without detaching.

(3) Quality Control and Inspection Areas

Quality assurance staff handle samples and packaging throughout the day. Using detectable plasters prevents the risk of cross-contamination during physical inspection, maintaining hygiene and traceability.

(4) Warehousing and Distribution

Though less exposure occurs here, staff may still handle heavy boxes or pallets, leading to minor injuries. Providing Blue Detectable Plasters in first-aid stations across warehouses ensures full compliance with food safety policies across all facility zones.

Why Suzhou Sunmed Blue Detectable Plasters Stand Out

Suzhou Sunmed, as a specialized Blue Detectable Plasters manufacturer, integrates advanced materials and precision production to deliver superior quality. Below are the core strengths that make Suzhou Sunmed products highly recommended for the food industry:

Metal-Detectable and X-Ray Detectable Materials

Suzhou Sunmed plasters are made with metal-infused film or foil layers that are fully detectable by standard factory inspection systems. This ensures that if a plaster detaches, it will not go unnoticed during production checks.

Highly Visible Blue Color

The deep, vibrant blue is chosen because it does not resemble any natural food color, ensuring quick visual detection. This unique feature minimizes contamination risks in high-speed food lines.

Strong Yet Skin-Friendly Adhesion

Suzhou Sunmed uses hypoallergenic medical-grade adhesive that provides long-lasting hold without irritating the skin. It adheres securely even under moist or warm conditions, ideal for workers in refrigerated or steam-rich food plants.

Breathable and Comfortable Fabric

The soft and flexible material allows skin to breathe while maintaining strong wound protection. Workers can continue tasks comfortably without frequent replacement.

Non-Stick Wound Pad

Every Suzhou Sunmed plaster includes a non-stick absorbent pad, protecting the wound while allowing it to heal cleanly. The pad effectively absorbs minor exudate, reducing infection risk.

Compliance with HACCP and Food Industry Standards

Suzhou Sunmed’s Blue Detectable Plasters are designed to meet global food safety regulations including HACCP, BRC, and ISO standards. Using compliant products demonstrates the manufacturer’s commitment to preventing contamination and protecting consumers.

Advantages of Using Blue Detectable Plasters in Food Factories

|

Advantage

|

Benefit for Food Factories

|

|

Enhanced Safety

|

Detectable by both human sight and metal detectors, preventing contamination.

|

|

Regulatory Compliance

|

Supports HACCP and industry audits, helping facilities maintain certification.

|

|

Worker Hygiene and Protection

|

Reduces infection risks from small wounds during production.

|

|

Operational Efficiency

|

Minimizes downtime caused by contamination incidents or recalls.

|

|

Brand Reputation Protection

|

Prevents foreign body contamination, safeguarding consumer trust.

|

By implementing detectable plasters across production areas, companies can significantly lower contamination risk and maintain a strong reputation for safety and quality.

The Practicality and Promotion of Suzhou Sunmed Blue Detectable Plasters

(1) Easy Implementation:

Factories can easily integrate Suzhou Sunmed Blue Detectable Plasters into existing first-aid protocols. They fit seamlessly into metal-detection and X-ray inspection systems already in use.

(2) Cost-Effective Prevention:

The cost of detectable plasters is minimal compared to the potential financial loss and reputation damage caused by a contamination-related product recall.

(3) Employee Awareness and Training:

Providing workers with Suzhou Sunmed Blue Detectable Plasters emphasizes a culture of safety and hygiene. It also reassures clients and auditors that contamination control is taken seriously.

(4) Suitable for Global Distribution:

Suzhou Sunmed’s plasters are packaged for bulk industrial supply or private labeling, making them ideal for distributors serving international food and manufacturing markets.

Why Food Manufacturers Choose Suzhou Sunmed

Food producers around the world rely on Suzhou Sunmed Blue Detectable Plasters because they combine safety, comfort, and compliance. Suzhou Sunmed continues to innovate by refining detection sensitivity, adhesive performance, and material durability to suit the demanding conditions of modern production facilities.

Suzhou Sunmed’s mission is to provide not only a product but a complete hygiene assurance solution—helping clients meet global standards and maintain consumer confidence.

Conclusion

In a food factory, every small detail contributes to overall safety—and Blue Detectable Plasters are one of the simplest yet most effective safeguards available.

They protect workers, prevent contamination, and ensure compliance with international food safety requirements.

By choosing Suzhou Sunmed Blue Detectable Plasters, food manufacturers gain:

Enhanced contamination prevention

Reliable metal detection performance

Comfortable, hypoallergenic wear for employees

Consistent compliance with HACCP and BRC standards

Suzhou Sunmed stands as your trusted partner in food industry hygiene solutions, delivering quality, safety, and reliability you can depend on.

English

English Español

Español русский

русский Français

Français Deutsch

Deutsch By Admin

By Admin